TikTok Service

TikTok Service

Facebook Service

Facebook Service

RedNote Service

RedNote Service

Amazon Service

Amazon Service

Against the backdrop of the booming beauty industry, cosmetic packaging containers have long transcended their role as mere "containers" and become the "first touchpoint" for dialogue between brands and consumers. From the exquisite glass bottles for high-end creams to the custom spray cans for niche fragrances, the manufacturing processes of packaging containers not only carry the basic mission of protecting products and maintaining their efficacy, but also shoulder the important value of conveying brand tone and arousing consumer resonance. As an enterprise deeply engaged in the manufacturing of plastic packaging containers for cosmetics, we, from a professional perspective, break down the full-process technological logic from design to delivery, presenting the sophisticated codes of cosmetic packaging manufacturing to colleagues in the industry.

I. Material Selection: The "Source Decision" Adapting to Needs

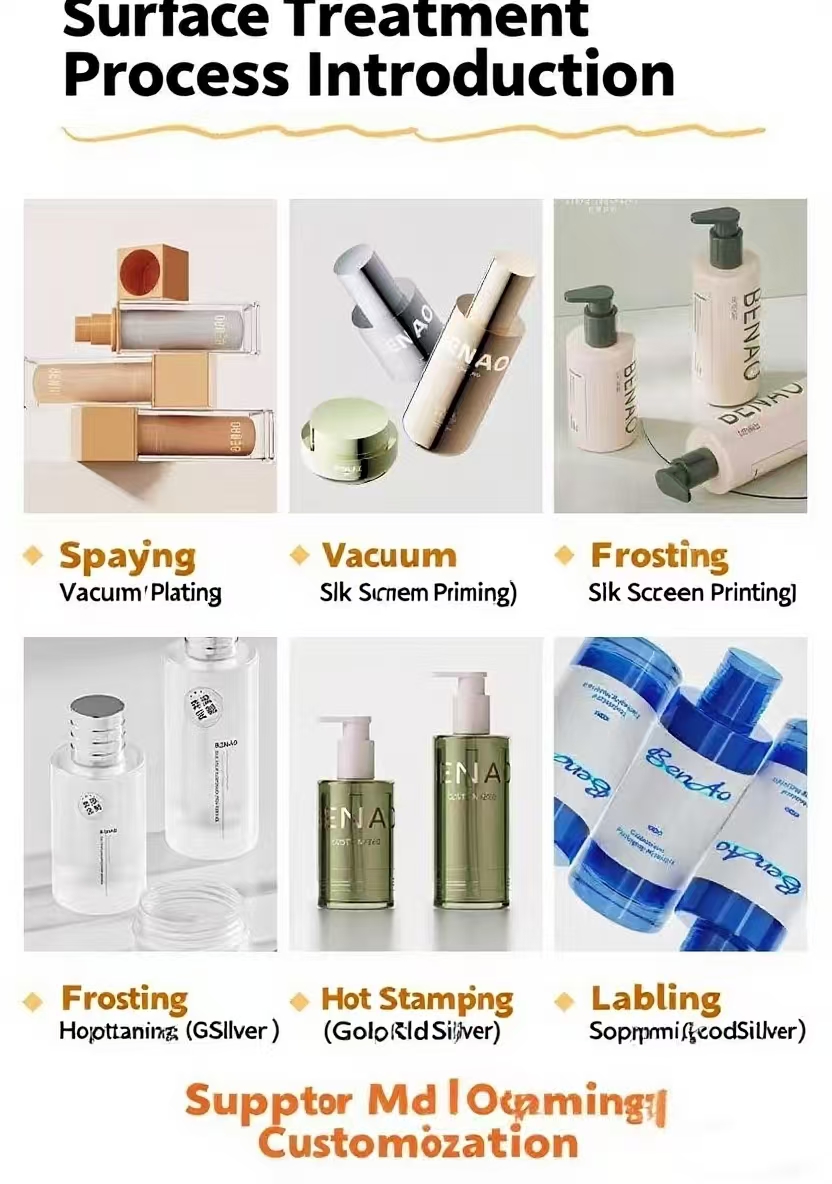

Spraying process: A spray gun is used to evenly spray water-based paint on the surface of glass bottles to create various effects, such as transparent color, solid color, glossy surface, matte surface, gradient, and pearl powder addition.

Silk-screen printing technology: Information such as capacity and brand name is printed on glass bottles to provide a clear visual effect.

Gold and silver stamping: Gold or silver aluminum foil is attached to the packaging surface by heating, creating a sense of凹凸 (relief) and a strong metallic texture, which enhances the luxury of the product.

Frosted effect: Chemical materials such as frosting liquid (powder) are used to attach to the surface of glass bottles by soaking or spraying to form a frosted effect.

Electroplating process: A uniform and dense metal coating is formed on the surface of glass bottles through chemical reactions, endowing the glass bottles with metallic luster and texture.

Aluminum oxide pump head: Appropriate aluminum oxide raw materials and additives are used, and it is formed by mold pressing. It has the characteristics of strong wear resistance, good corrosion resistance and high-temperature stability.

3D printing technology: Objects are constructed by layer-by-layer printing using digital model files, and the printed text or patterns have an obvious sense of凹凸 (relief).

Water transfer printing technology: Patterns are irregularly printed in water to form patterns with rich layers and bright colors, which are commonly seen on lids with imitation wood grain patterns.

Labeling process: Labels or markers are attached to containers, which is low in cost and environmentally friendly.

Glossy surface effect: The glossiness of the glass bottle surface is created by applying gloss oil.

Matte surface effect: The matte effect on the glass bottle surface is formed by applying matte oil.

Semi-transparent effect: The packaging material has a sense of transparency, showing the unique charm of the product.

Solid color effect: The packaging material has no transparency, providing a stable visual effect.

Gradient effect: Different colors are sprayed on the surface of glass bottles to achieve a naturally gradual transition effect.

II. Surface Treatment: A Value-adding Link That Endows Containers with "Soul"

1. Silk-screen Printing and Gold Stamping: On the surfaces of bottle bodies and lids, silk-screen printing technology can realize multi-color gradients and accurate presentation of brand logos; gold stamping process endows high-end products with a metallic texture. For example, the gold-stamped LOGO on the lid of a cream jar, which transfers the metal foil to the plastic surface through high temperature of 120-150℃, enhances the brand premium.

2. Spraying and Electroplating: The spraying process gives containers diverse textures such as matte, high-gloss, and pearlescent. By controlling spray gun parameters and coating formulas, surface performance of "wear resistance for more than 500 times" can be achieved (suitable for frequently used perfume bottle caps); vacuum electroplating technology endows plastic containers with metallic luster, and it is more environmentally friendly than traditional electroplating, which is widely used in eye shadow cases, lipstick tubes and other products.